Brazed Plate Exchangers

L Exchanger

Brazed plate heat exchangers are the perfect solution that allows for maintaining high thermal performance at low operating costs.

The L series brazed plate heat exchangers are a perfect solution for heating and cooling installations. Permanently connecting heating plates during the brazing process in the vacuum furnace guarantees reliable operation at low operating costs. Extensive heat exchange area allows for highly efficient operation in demanding conditions.

Wide range of types, sizes, and numbers of plates and connections allows for optimizing the selection to particular application. Copper or stainless brazing and the double wall option offer additional application possibilities. Brazed exchangers guarantee reliable, long-term operation.

- Turbulent flow thanks to the special corrugation pattern of the heating plates.

- Airtight design – permanent connection of the plates during the vacuum brazing process, using the copper or stainless LUNATM brazing.

- Low operating costs – beneficial exchanger price and long-term maintenance-free operating period.

- Saving space – extensive heat exchange area in small exchanger dimensions.

- Reliable – adapted to operate in demanding conditions of temperature and pressure differences. Optimized for any use – thanks to the single and double flow version, wide range of connections and the selection of proper number of plates.

Luna Exchanger

LUNATM brazed plate heat exchangers are a materially homogenous design with high hygienic level and high resistance to temperature changes and corrosion.

Thanks to being made entirely of stainless materials they can be used in heating or refrigerating systems with high sanitary requirements. They are also a perfect solution in case of aggressive media, e.g. aggressive water from water supply system, ammonia, as well as in systems with galvanized pipes.

- Materially homogeneous design made entirely of stainless materials.

- Stainless LUNATM brazing.

- High hygienic level.

- Long-term life span.

- Resistant to temperature changes and corrosion.

- To be used with aggressive media.

R Exchanger

R brazed plate heat exchangers are intended for cooling or heating systems to work as evaporators or cooling medium condensers.

Specially adjusted heating plates corrugation pattern ensures effective cooling medium evaporation or condensation. It is a proven solution for heat pumps or refrigerating units. Allows for working with cooling medium with pressure up to 45 bar.

Refrigerant Distribution System (RDS) enables efficient distribution of medium droplets and their even evaporation, regardless of heating channel position against inlet connection. This solution allows for effective utilization od the entire heat exchange area in the exchanger.

- Effective cooling medium evaporation or condensation thanks to the specially formed channels.

- RH version allows for working with medium with pressure up to 45 bar and has been optimized for the R410A medium.

- Dynamic boiling medium distribution system (RDS).

- Copper or stainless LUNA brazing.

- High head exchange coefficient.

- Solid, compact design.

SafePLATE Exchanger

The SafePLATE exchangers with a double-wall system are intended for systems where it is crucial to help protect media from mixing and quickly detect any possible leaks.

The SafePLATE exchangers have been designed for applications requiring high heat exchange efficiency, where it is crucial to help prevent the working media from mixing in case of internal leakage. Such leakage, although very unlikely, may result from corrosion or hydraulic impact in the system.

In such case the specially designed double wall layout and a slot on the side surface of the exchanger leads the leakage outside, which allows for its quick visual detection and undertaking appropriate preventive measures.

- Double wall system—helps to prevent potential mixing of working media.

- Quick detection of internal leakage—leading the leakage outside.

- Long-term life span—made of corrosion resistant stainless steel.

- High performance and compact size.

AS Exchanger

Special arrangement of the channels ensures maximum heat transfer efficiency on the lower flow rate side with a minimum pressure drop on the secondary circuit.

The biggest advantage of the asymmetric heat exchanger is its compact size and the possibility of using lower power pumps in central heating systems. In many cases, the efficiency of asymmetric heat exchangers can be 18 % higher compared to standard brazed plate heat exchangers.

- Greater capacity due to the use of a corrugated heating plate that creates an additional channel.

- Lower water pressure drops—secondary side.

- Higher efficiency—increased maximum water flow.

- Compact size.

- Greater flow turbulence—primary side.

- Less refrigerant requirement.

- Low carbon footprint.

- An option is available made of stainless materials—LUNA.

L Ultra Exchanger

The L ULTRA heat exchanger is an eco-friendly solution that combines optimal efficiency of brazed plates with high pressure resistance.

The heat exchanger frame ensures maximum safety, handling pressures up to 140 bar. Plus, the design of the brazed plates minimizes the risk of leaks, enhancing the device’s reliability. It’s also important to note that using CO₂ as a refrigerant helps reduce greenhouse gas emissions, which is crucial for environmental protection.

So, L ULTRA heat exchangers are not just efficient but also green, making them perfect for modern cooling and heating systems. These exchangers are available in our offer in two material options – brazed with copper or with LUNA stainless materials.

- Optimal efficiency.

- High pressure resistance designed to withstand high-pressure conditions up to 140 bar.

- Material options—can be brazed with either copper or stainless materials LUNATM.

- Ideal for CO2 applications—excellent performance specifically suited for CO2-related applications.

- Space-saving design.

- Suitable for a wide range of applications.

Plate and Frame Exchangers

JAG F Exchanger

JAG F plate and frame heat exchangers are a new, revolutionary solution, ensuring not only increased flow turbulence, but also extensive heat exchange surface.

The innovative JAG heating plate corrugation pattern, developed through extensive product research, enables a more compact, lighter, and, above all, more efficient exchanger, perfectly tailored to individual requirements. The new “jagged” channel design increases flow turbulence, which improves heat exchange and also decreases sediment accumulation.

The additional benefit is an extensive heat exchange surface and decreased overall pressure drops. JAG F plate heat exchanger also features a range of technical solutions for the frame construction that make the highly efficient JAG F plate heat exchanger a reliable solution in many applications.

- High thermal performance thanks to innovative heating plate corrugations pattern.

- Technical solutions facilitating the exchanger installation and operation.

- Option to adjust the exchanger design to the required installation operating parameters by selecting proper number and size of the heating plates.

- Heating plates made of stainless steel or titanium to be used in aggressive media systems or pools with salt water.

- Dismountable design—allows for cleaning and extension, if necessary.

- Wide range of products.

- Made of stainless steel (optional).

- The available double-wall system option helps prevent media mixing and enables quick leak detection in critical installations.

F Exchanger

Series F plate and frame gasketed heat exchangers are reliable, proven devices that are the optimum solution for the heat exchange process especially in handling of technological processes.

They have the highest heat exchange efficiency among the solutions available on the market and may be used even in the case of very small differences in media temperatures. Very high design flexibility of the plate and frame exchanger allows to adjust it to the required operating conditions thanks to a broad range of plate sizes, plate materials, gasket materials and a selection of various geometry of flow channels.

Dismountable design of the exchanger allows its extension and disassembly in order to perform regular maintenance activities, including mechanical cleaning.

- High heat performance.

- Option to adjust the exchanger design to the required installation operating parameters by selecting proper number and size of the heating plates.

- Compatible with all heat sources.

- Heating plates made of stainless steel or titanium to be used in aggressive media systems or pools with salt water.

- Dismountable design—allows for cleaning and extension, if necessary.

- Wide range of products.

Multisection Exchanger

The growing consumer awareness about food is forcing food processing companies to meet increasingly higher technological requirements.

We offer a range of stainless steel heat exchangers, which are crucial components in the food industry. Our equipment streamlines the processes of heating, cooling, and pasteurization.

Stainless steel heat exchangers are an extremely important element in the production process, providing not only effective and fast heating or cooling, but also durability and hygiene. Heat exchangers increase production efficiency while saving energy. The pasteurization process is crucial for ensuring food safety and extending its shelf life.

- High efficiency.

- Effective energy recovery.

- High level of hygiene.

- Made of stainless materials.

- Corrosion resistance.

- Certified gaskets.

- Energy savings.

- Expandability.

- Wide range of products.

Shell and Tube Exchangers

DNA Exchanger

DNA provide a number of hydraulic and heat exchange improvements, preserving the features and benefits of the traditional shell and tube design.

DNA reaches a significantly higher heat exchange coefficient compared to standard solutions. Distribution of the tubes in the shell allows for more efficient operation in high flow installation (e.g. exhaust, hot air, low pressure steam). Thanks to its unique tube side design, the DNA exchanger is compatible with high-viscosity media, retaining a high level of heat exchange.

The unique design of the DNA exchanger allowed for a lower and lighter device, made with significant saving of material, at the same time preserving high mechanical resistance characteristic for shell and tube exchangers.

- Spiral tubest ensure turbulent rotational flow, which doubles the heat exchange coefficient.

- Low pressure drops and lack of dead zones.

- Extensive heat exchange surface in compact heat exchangers.

- Ideal for operation with high-flow media.

- Made entirely of stainless steel, corrosion resistant.

- Possibility to make the exchanger from titanium resistant to aggressive substances.

P-LINE Exchanger

Hexonic P-line heat exchangers meet the challenges offered by the pharmaceutical industry. They also meet its restrictive hygienic standards imposed by inspection authorities and the industry.

They were designed so to minimize the risk of contamination and ensure safe and sterile operation. Thanks to the double tubesheet, the exchanger prevents mixing the pharmaceutical product with the other medium even in the case of leakage and allows for immediate detection of potential malfunction.

Thanks to the tubes with low roughness and proper connector placement, the connector can be completely emptied using only the force of gravity. The polished inner tube surfaces hinder sediment accumulation, which is crucial for maintaining high hygienic standards in the pharmaceutical industry. The exchanger design also ensures very low pressure losses, while high quality materials ensure long-term and safe operation.

- Designed to operate in pharmaceutical production, meets the highest hygienic standards.

- 3-A certified.

- Manufactured in accordance with cGMP, PED, ASME.

- Double tube sheet constitutes additional protection for the pharmaceutical product before mixing it with the other medium.

- Surfaces that come into contact with pure medium have been polished to Ra ≤ 0.5 µm/19,7 µin roughness, which allows for precise exchanger cleaning.

- Made entirely of stainless steel.

- One, two or four pass design.

- Horizontal and vertical models available.

ST Exchanger

ST tube in tube heat exchangers find their application where fluids of high viscosity, density or high fiber or solid particle contamination are subjected to heat treatment, e.g. at waste water treatment plants.

The presence of different types of mechanical contamination causes their sedimentation on the walls, which blocks the flows in the exchanger. Large diameter of the ST exchanger tubes ensures their free flow and the dismountable design allows for mechanical cleaning of the heat exchange surface.

Stainless steel make ensures corrosion resistance and the simple design ensures long-term failure-free operation.

- Dismountable design—allows for mechanical cleaning.

- Option to increase heat exchange surface.

- Made of stainless steel.

- Broad range.

B Exchanger

B pool heat exchangers have high thermal performance. They are the perfect solution in high-flow systems, in particular pool systems of different types and sizes.

B type exchangers are shell and tube exchangers equipped with straight corrugated tubes. They can be used in systems with high medium flow in comparison to transferred thermal power. It is a proven solution for pool and solar systems or small oil preheating systems.

The use of corrugated tubes intensifies heat exchange and increases self-cleaning possibilities. Compact, welded B type exchangers are highly durable and reliable.

- Stainless steel make – appropriate for pools with treated water.

- Resistant to corrosion caused by aggressive substances in pool water (e.g. fluorine, chlorine).

- High flow rate with low pressure losses – eliminates the necessity to use bypasses.

- Compact size.

- Airtight welded design.

- Turbulent flow corrugated tube surface intensifies heat exchange and hinders sediment accumulation

REV Exchanger

REV pool heat exchangers achieve very high heat exchange coefficient thanks to the 3-pass tube bundle.

REV heat exchangers are intended for use mainly in swimming pool installations. The main priority in their design was to improve heat exchange conditions. This was achieved by using the 3-pass design of the tube bundle, which results in better utilization of source thermal power. Additionally, thanks to the short path of pool water (heated medium) through the exchanger, the flow speed remains high.

Corrugated tubes increase flow turbulence, which further intensifies heat transfer. REV heat exchangers are made in two material versions – stainless steel or titanium. REV works perfectly with heat pumps, solar panels, but also standard heat sources, e.g. gas-fired boilers.

- Unique 3-pass tube bundle – allows for better utilization of source thermal power and achieving perfect heat exchange conditions.

- Stainless steel make – appropriate for pools with treated water.

- Resistant to aggressive substances in pool water, such as fluorine and chlorine.

- Corrugated tubes cause turbulent flow, which intensifies heat exchange and hinders sediment accumulation.

- Low flow pressure drop on shell (pool) side.

- Perfect for operating with heat pumps and solar panels.

TI Exchanger

The L ULTRA heat exchanger is an eco-friendly solution that combines optimal efficiency of brazed plates with high pressure resistance.

The heat exchanger frame ensures maximum safety, handling pressures up to 140 bar. Plus, the design of the brazed plates minimizes the risk of leaks, enhancing the device’s reliability. It’s also important to note that using CO₂ as a refrigerant helps reduce greenhouse gas emissions, which is crucial for environmental protection.

So, L ULTRA heat exchangers are not just efficient but also green, making them perfect for modern cooling and heating systems. These exchangers are available in our offer in two material options – brazed with copper or with LUNA stainless materials.

- Optimal Efficiency.

- High-Pressure Resistance – designed to withstand high-pressure conditions up to 140 bar.

- Material Options – can be brazed with either copper or stainless materials LUNATM.

- Ideal for CO₂ Applications – excellent performance specifically suited for CO₂-related applications.

- Space-saving design.

- Suitable for a wide range of applications.

Shell and Coil Exchangers

HAD Exchanger

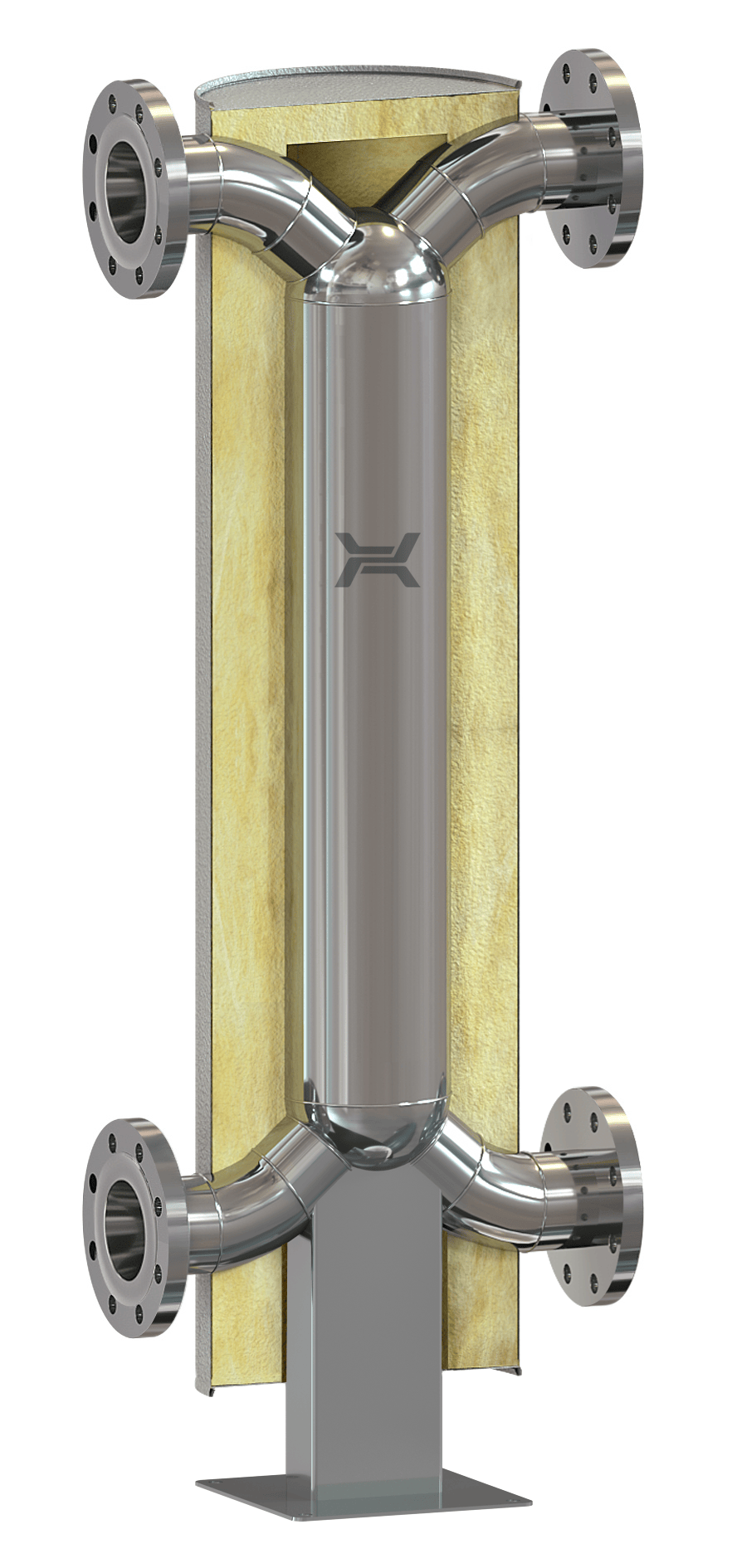

HAD shell and coil heat exchanger is a fully equipped, installation-ready kit consisting of an exchanger, mount and insulation.

As a result of advanced design works, HAD has all the benefits of the shell and coil exchangers plus new solutions such as the horizontal position of the connections; it also comes with an insulation and a mount.

The new HAD features facilitate mounting it to a horizontal installation and shorten and facilitate the whole process. Additionally HAD is a perfect solution in terms of economy, ensuring a cost-efficient solution.

- Easy installation – ensured by delivery with pre-installed mount and insulation.

- Saving space – compact size of the exchanger and the possibility of vertical installation reduce the space necessary for installation.

- Low operating costs – the X-shaped design of the connections and corrugated coil tubes make the exchangers more resistant to deposits.

- Easy installation – ensured by delivery with pre-installed mount and insulation

- Saving space – compact size of the exchanger and the possibility of vertical installation reduce the space necessary for installation.

- Low operating costs – the X-shaped design of the connections and corrugated coil tubes make the exchangers more resistant to deposits.

H Exchanger

H type shell and tube heat exchangers are an economic solution for small CH and DHW systems.

H type exchangers are the extension of the shell and tube exchangers range with the smallest exchangers built based on tube coil. High performance and compact size against heat exchange surface make them perfect solution for low power systems. They were made to meet the requirements od the smallest industrial systems and heating substations.

Especially the ones where plate exchangers cannot be used for various reasons (e.g. high contamination or aggressive environment). Versions with threaded and flanged connections are available for maximum adjustment of the exchanger to local conditions and to facilitate mounting during installation.

RAD Exchanger

Heat exchangers dedicated for ground source heat pumps.

Direct refrigerant inlet into each of the heat exchanger tubes ensures uniform medium distribution. RAD has a high heat

transfer coefficient and is designed for modern A2L refrigerants such as R32, R452B, R454B. With compact dimensions and vertical installation, the exchanger’s footprint is greatly reduced. RAD has been designed to work with pressures up to 45 bar.

- Easy installation – ensured by delivery with pre-installed mount and insulation.

- Saving space – compact size of the exchanger and the possibility of vertical installation reduce the space necessary for installation.

- Low operating costs – the X-shaped design of the connections and corrugated coil tubes make the exchangers more resistant to deposits.

- Easy installation – ensured by delivery with pre-installed mount and insulation.

- Saving space – compact size of the exchanger and the possibility of vertical installation reduce the space necessary for installation.

- Low operating costs – the X-shaped design of the connections and corrugated coil tubes make the exchangers more resistant to deposits.