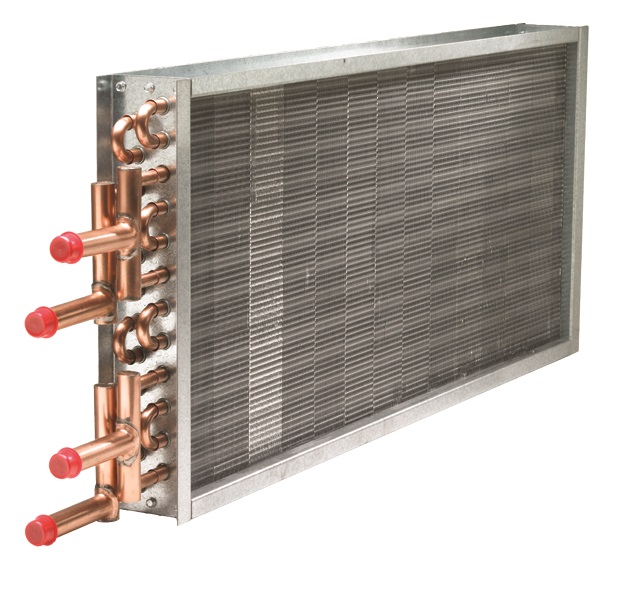

Hot Water Coils

Capital Coil & Air hot water coils are used in a wide variety of HVAC air heating applications for both air handlers and duct work. Hot water coils typically consist of between 1-3 rows of tubes. Most hot water coils have air entering the system at a temperature ranging from 40-65°F while hot water enters the coil at a temperature around 180°F. Standard and custom designs are available for new and retrofit installations. These hot water coils come with a huge selection of tube, fin and material options.

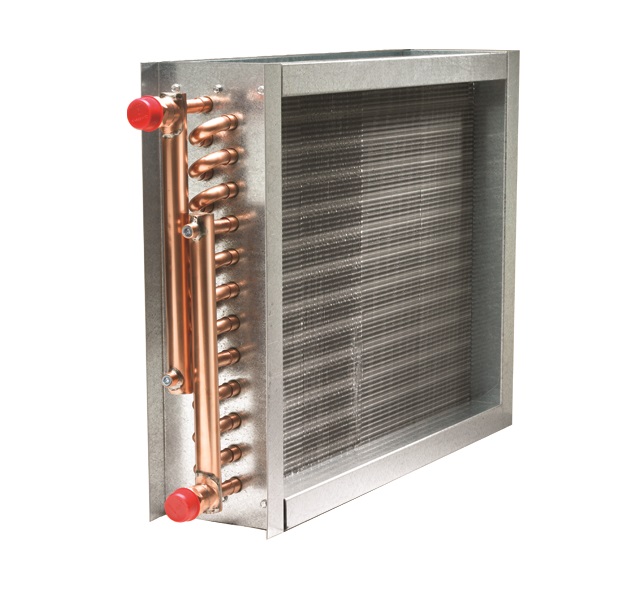

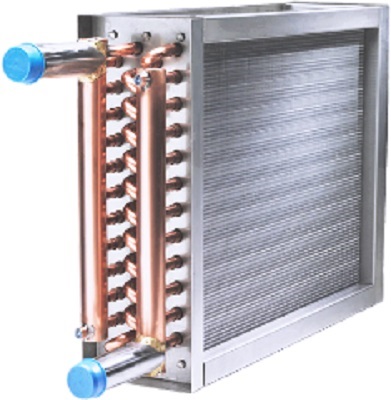

Chilled Water Coils

Capital Coil & Air chilled water coils are used in a wide variety of HVAC air cooling and dehumidifying applications. Chilled water coils typically consist of between 3–12 rows of tubes. Most chilled water coils have air entering the system at a temperature ranging from 75° F to 95° F (return or outside air), while chilled water enters the coil at a temperature around 42-45°F. Standard and custom designs are available for new and retrofit installations. These chilled water coils come with a huge selection of tube, fin and material options.

Condenser Coils

Capital Coil & Air condenser coils are used in a wide variety of HVAC heat recovery and condensing applications. Condenser coils typically consist of between 1-4 rows of tubes. These condenser coils come with a huge selection of tube, fin and material options including 5/16” OD copper tubing. Standard and custom designs are available for new and retrofit installations.

Standard Steam Coils

Steam coils are made with 5/8” tubes and the tube thickness can differ based on the application and steam pressure. Capital Coil recommends standard steam coils when entering air temperatures are above 40ºF. Capital also offers stainless steel, carbon steel and cupro-nickel tubing for industrial applications for your steam coils.

Industrial Coils

Capital Coil & Air manufactures and designs a wide assortment of heavy-duty coils to withstand the environment of industrial applications. Standard and custom designs are available for new and retrofit installations. These coils are manufactured from quality materials that are heavier grades and thicknesses. This ensures dependable performance and longevity, even in the most demanding conditions. Capital Coil & Air provides high quality industrial coils designed for easy maintenance and low operating costs.

Hot Water Duct Booster Coils

Capital Coil & Air can manufacture a Hot Water Duct Booster Coil to your exact specifications for any equipment, any brand. The Hot Water Duct Booster Coils are built with a 1” flange or with slip & drive casings. Capital offers the most extensive offering of sizes that can be built and shipped in 3-5 business days on most orders.

Divided Water/Glycol Coils

Capital Coil’s Divided Coils are the ideal solution for replacement applications where there is limited access for installation of a full-length coil. This feature allows for shipping the coils in specified lengths that will fit into limited-access areas. The coils are manufactured with heavy steel endplates that are bolted together in the field, and our gasket insures leak-free installation. Close proximity of the endplates to the fin pack allow for maximum fin length on the installed coil.

Direct Expansion Coils

Our DX evaporator coils are available in 1/2”, 3/8”, 5/16” or 5/8” OD copper tubes with a distributor based on the coil performance and specific refrigerant. Capital Coil is one of the few manufacturers that offers 5/16” tubing for DX and condenser coils. Capital Coil offers face splits, row splits, and intertwined options. We also offer insulated cabinet/drain pans for ducted applications.

Insulated Cabinet Coils

Insulated Cabinet Coils are often applied to provide additional cooling to an existing HVAC system. They can provide incremental cooling capacity without an expensive upgrade to rooftop or air handling units. Insulated Cabinet Coils are well-suited for schools, restaurants, healthcare and pharmaceutical manufacturing facilities; and many other types of buildings as well.

Replacement Tube Bundles

Capital Coil builds replacement tube bundles for water/water exchangers and steam/water exchangers. We can duplicate the bundle diameter, length, tubesheet, and bolt hole pattern. You slide the old bundle out and slide the new bundle in without a lot of extra work on the jobsite. Special materials are available for high pressure steam, boiler water, or high temperature hot water.